Embracing the Industry 4.0 Revolution

The pharmaceutical sector faces ongoing challenges, such as globalization, greater supply chain complexity, price and cost pressure, and the advent of personalized medicine.

The pharmaceutical sector faces ongoing challenges, such as globalization, greater supply chain complexity, price and cost pressure, and the advent of personalized medicine.

Digitalization and the complete adoption of all that Industry 4.0 has to offer will be at the centre of helping the pharmaceutical sector generally, and the serialization track-and-trace sector specifically, meet these challenges.

What will the true impact of Industry 4.0 be, and how prepared for it are we?

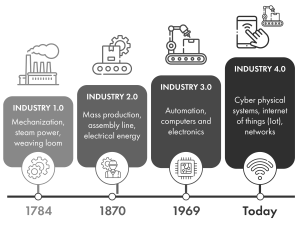

While Industry 4.0 has been called a new industrial revolution, its implementation will more likely resemble an evolution in which digitalization and automation meet very complex product portfolios and life cycles.

Digitalization will connect everything, creating new levels of transparency and adaptivity for a digitalized plant floor. This will enable faster decision making and provide in-line and in-time control over business, operations, and quality. It will also require higher levels of security, since connected systems heighten vulnerability.

A combination of cyber-physical systems, the Internet of Things and the Internet of Systems will power Industry 4.0 and allow the smart factory to become a reality. As a result of the support of smart machines that keep getting smarter as they get access to more data, the global pharmaceutical sector will become more efficient and productive and less wasteful.

Ultimately, it’s the network of these machines that are digitally connected with one another and create and share information that will result in the true power of Industry 4.0.

Indeed, we are already seeing the implementation of agile supply chain regulation which will require a strong industry-standard open interface and interoperability.

To do this, the hardware and the software among different vendors needs to be much more aligned and should work much closer together, resulting in much more open and cooperative serialization processes. Machines need to speak to each other in a common language, regardless of the manufacturer. The importance of this cannot be over-stated. To be able to track every single item, at every single stage of the process from source to supply to consumer, is essential.

This will be a particularly important for the everyday production of personalised medication. It will give all concerned – from the producer through to the end consumer – the confidence their individual needs are being met and will enable complex prescriptions to be produced as a matter of routine.

This will be made more difficult without the wholesale adoption of Industry 4.0 and the coordinated benefits it will bring to the track and trace sector.

Conclusion

Advanco has been calling for a much more open track-and-trace sector for many years now and we are looking forward to the progress that Industry 4.0 will bring to this aim. We wholeheartedly call for all other track-and-trace providers to share this view so we can all work together for the good of the pharmaceutical sector and the eradication of counterfeit products, something that continues to blight the world.

View the original article here.